DRAIN PLUG

ALL BROWN DAVIS STEEL FUEL TANKS COME WITH A DRAIN PLUG FOR DRAINING CONTAMINATED FUEL OR EVEN COLLECTING SOME FUEL FOR A MATE.

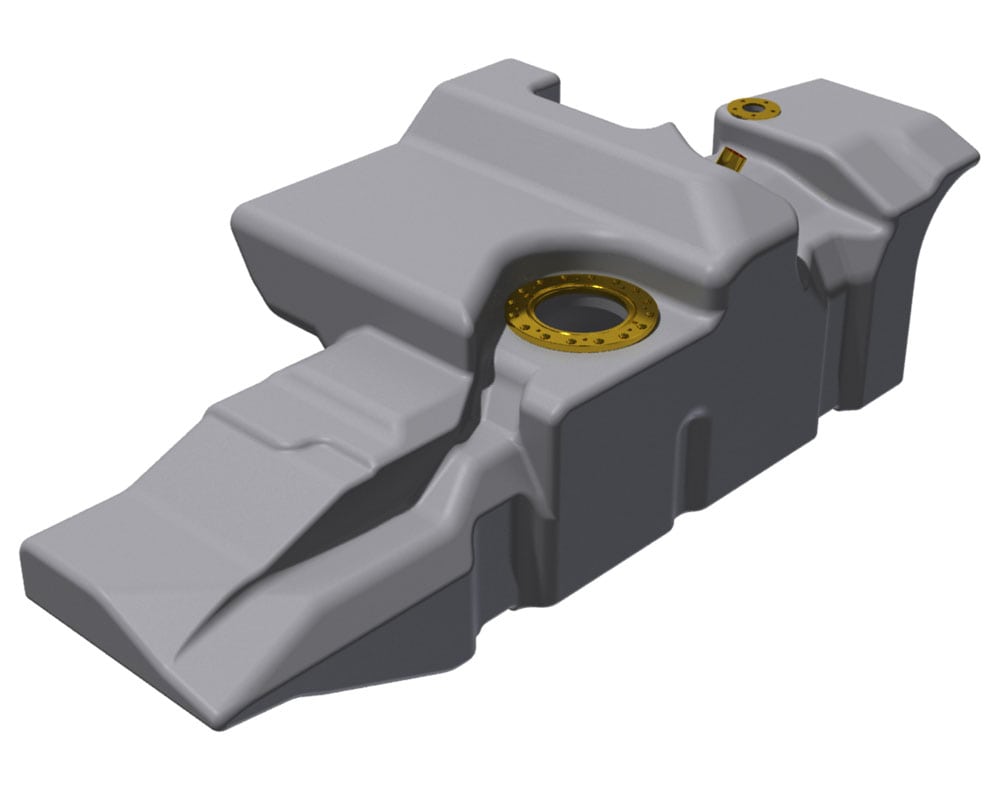

Brown Davis long range fuel tanks are an engineered solution to enable you to travel further with less fuel stops. They are designed to give maximum fuel capacity without affecting ground clearance, ramp over or departure angle, whilst being exceptionally strong to withstand the most rigorous of conditions. Brown Davis long range tanks allow you to travel to the most remote parts of the globe where the standard tank wouldn’t take you.

Brown Davis manufactures a wide range of both Steel and Poly tanks so finding the right type of tank for your vehicle is crucial. Many factors need to taken into account so below are the highlights of both our steel and poly long range fuel tanks.

ALL BROWN DAVIS STEEL FUEL TANKS COME WITH A DRAIN PLUG FOR DRAINING CONTAMINATED FUEL OR EVEN COLLECTING SOME FUEL FOR A MATE.

ALL BROWN DAVIS STEEL LONG RANGE FUEL TANKS HAVE INTERNAL BAFFFLES, THIS MINIMIZES FUEL SLOSH AND MOVEMENT. ALSO PROVIDING THE TANK WITH GREATER STRENGTH AND INGEGRITY.

ALMOST ALL BROWN DAVIS STEEL LONG RANGE FUEL TANKS HAVE AN INTERNAL SWIRL POT. THIS DESIGN TRAPS FUEL AROUND THE PICK UP SO THAT YOU CAN RUN DOWN TO THE LAST FEW LITRES.

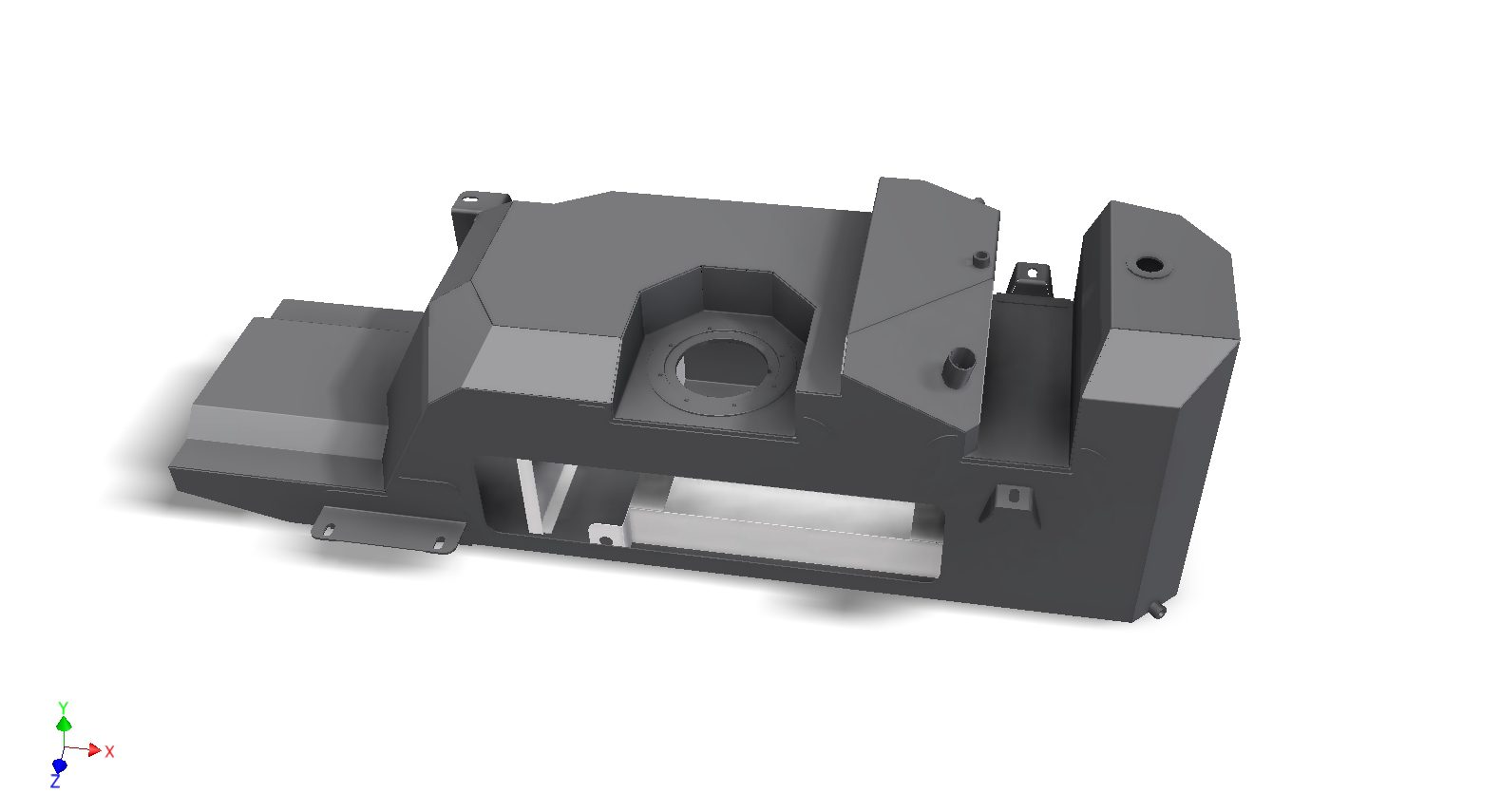

For 4WDs and tourers planning to head off the beaten track, our aluminized steel Long Range Fuel Tank is the best option.

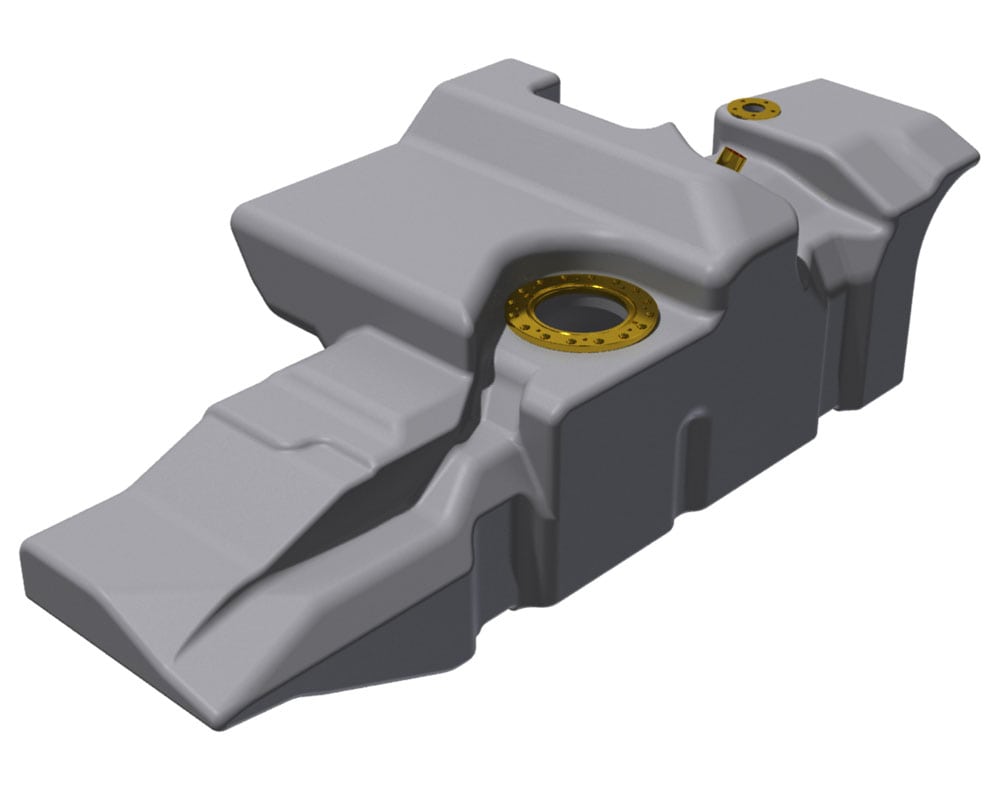

IF WEIGHT IS CRITICAL IN YOUR VEHICLE ON AVERAGE MOST LONG RANGE POLY TANKS ARE 10-15KG LIGHTER THAN STEEL TANKS.

For fleet managers and customers sitting primarily on surfaced road, poly long range fuel tanks is a great option.

Tapered approach angle to reduce frontal impact and improve ramp over clearance

Fuel baffling system to prevent fuel slosh and to strengthen tank structure

Gusseted brackets with double thickness pads to spread tank mounting loads

Fuel pump sender flange designed to re-use the vehicle’s original equipment

Swirl pot designed to carrel fuel around the pick up point

Roll over check valve and expansion box for fuel expansion and venting

Fast fill breather for rapid filling and to reduce bowser shut off

Filler tube, connects to vehicles original filling point

Cushion clamps to retain fuel lines to prevent damage and kinking

Magnetic drain plug, horizontal and flush mounted to prevent damage

Tapered approach angle to reduce frontal impact and improve ramp over clearance

Fuel pump sender flange designed to re-use vehicles original equipment

Roll over check valve and expansion box for fuel expansion and venting

Filler tube, connects to vehicles original filling point

Fast fill breather for rapid filling and to reduce bowser shut off (works with fast fill)

Fuel line locators- for ease of fitment and to prevent kinking

The Brown Davis Long Range Fuel Tank range consists of 3 main types. These are designed to best suit specific vehicles and the users applications.

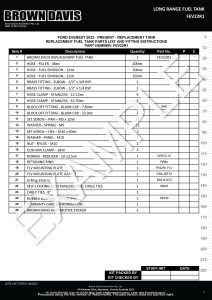

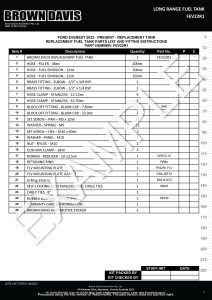

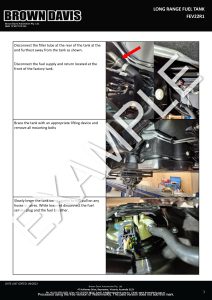

Replacement Long range tanks are designed to replace the vehicles standard fuel tank with an increased fuel capacity. The tank is a simple bolt in solution to increase your vehicles driving range. On the current model dual cab ute range the fuel capacity increase is around 1 00%. Replacement fuel tanks are designed to minimise vehicle modifications utilising the standard fuel gauge, pump assembly and fill point for a simple installation. All Brown Davis fuel tanks come with a flush mounted drain plug for easy draining in the event of contaminated fuel. The tanks come with all parts and hardware supplied.

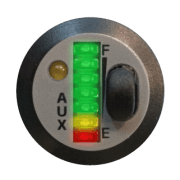

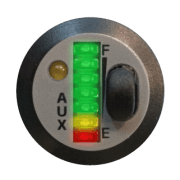

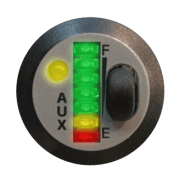

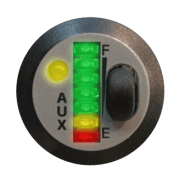

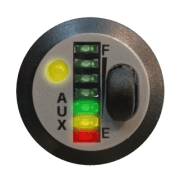

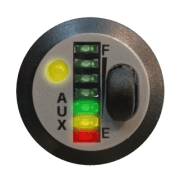

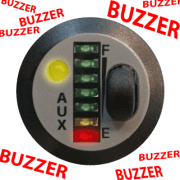

This system is designed to pump the fuel from the Brown Davis auxiliary fuel tank into the vehicles standard fuel tank. At the flick of a switch, fuel will replenish your vehicles standard tank, which in turn is then fed to the engine. An LED gauge is supplied to show the driver the fuel level of the auxiliary fuel tank at all times. When the auxiliary tank becomes empty an automatic alarm will sound to alert the driver to switch the pump system off. This prevents the pump from continuously running, preventing fuel pump failure. All parts and hardware for installation are supplied.

This system is designed as a changeover system, which means at the flick of a switch the driver can independently feed the engine directly from the vehicles main tank or the Brown Davis auxiliary tank. This allows the operator to empty either tank to evenly distribute weight across the vehicle. (ie: empty the rear tank first for towing purposes.) This is the same system as used in the early Land Cruiser 79 series single cabs and 100 series with twin tanks. All parts and hardware for installation are supplied.

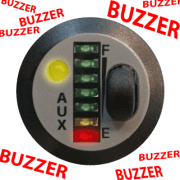

Fuel pumps burning out is now a thing of the past. Brown Davis has developed a new auxiliary fuel tank gauge, switch and buzzer unit to be supplied with most Brown Davis auxiliary transfer fuel tanks. the small unit is no bigger then a 10 cent coin and can be mounted nicely in vehicles dashes.

THE LED GAUGE WILL SHOW TANK LEVEL AT ALL TIMES EVEN IF PUMP IS NOT RUNNING.

WHEN BUTTON IS PRESSED THE PUMP WILL BEGIN TRANSFERRING FUEL ACROSS TO YOUR VEHICLES MAIN TANK. THE ROUND YELLOW LED LIGHT SHOWS PUMP IS RUNNING

AS FUEL IS BEING TRANSFERRED ACROSS THE LED LIGHTS WILL SHOW FUEL LEVEL REMAINING IN YOUR AUXILIARY TANK. AT ANY STAGE YOU CAN PRESS THE BUTTON AND STOP THE TRANSFER OF FUEL.

WHEN TANK IS COMPLETELY EMPTY A BUZZER WILL SOUND AS A REMINDED TO TURN THE PUMP OFF. LEAVING FUEL PUMPS ON FOR LONG PERIODS OF TIME CAN BURN THEM OUT

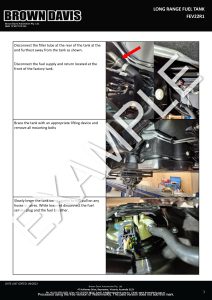

The Brown Davis Chevrolet Silerado 2500 tank comes with step by step instructions that walk you through every step of the install.

Since the beginning, Brown Davis has taken pride in the construction of our tanks, our Next-Gen Ranger tank is no exception. Our tanks are made with quality and care, from the materials we use to the stringent pressure testing, they are prepared for the harshest conditions.

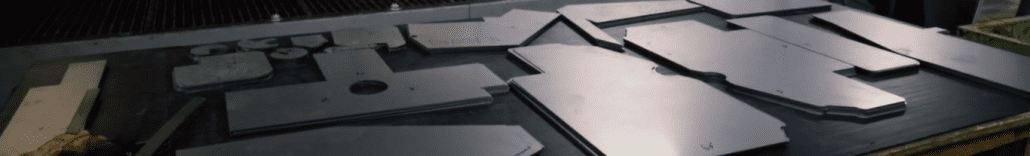

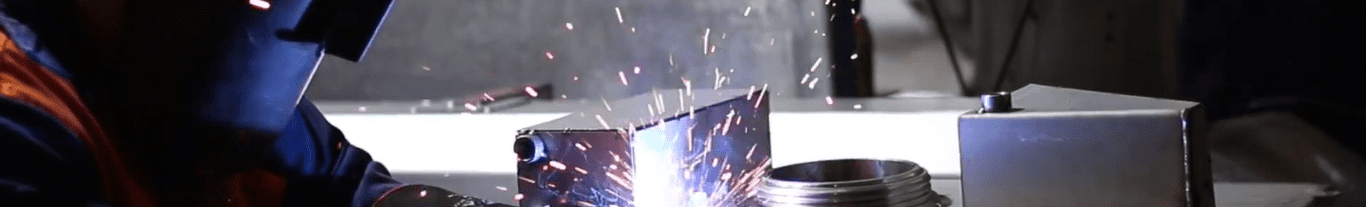

Manufacturing our steel tanks starts with laser cut aluminized steel. With this material, your tank will have the strength and durability of steel, and the anti-corrosive properties of aluminum to make sure their is no rust.

Before welding the tank, we use specialized machinery to fold the laser cut aluminized steel to decrease the amount of time and labor put into welding. Folded parts also have superior strength to welded parts.

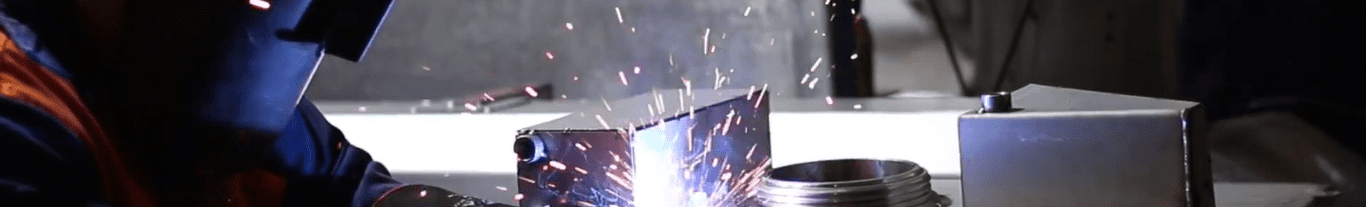

Next, our experienced welders add the brackets, swirl pot and baffles to the tank and then weld it all off. We use jigs to locate the brackets for each individual tank so installation is as consistent and easy as possible for every vehicle.

Lastly, we take it through an air pressure test. This involves a soap test, submersion test and a pressure gauge. These techniques help us identify any rare leaks and where they’re coming from. If air isn’t coming out, fuel definitely isn’t.

For total peace of mind Brown Davis offers a 3 year warranty on all its fuel tanks. With an Australia wide network built over the 40+ years in the industry, you can go away on your longest journey knowing you will have full support with any issues.

Don’t see your vehicle listed above? Many products are not listed on our website. Feel free to contact us for more infomation (03) 9762 8722